High Quality for High-End Tin Box - Small Child Resistant Tin Cube – CR

High Quality for High-End Tin Box - Small Child Resistant Tin Cube – CR Detail:

Description

This child resistant version is the same as Gen2 from appearance. It applies special elastic tinplate with complex process for tin body to form this stable child resistant tin cube. There are two slots in lid locks the rolled inside bottom, pushing and lifting lid is the only method to open this tin cube. Designing the child resistant mechanism in lid will ensure no deformation when opening or close this tin cube, three pieces structure ensures this child resistant feature that can be applied all the size, lid-bottom seperating version ensures jellies can be packed directly.

Certified Child Ressitant Version

Custom Printing

Various Usage

This small child resistant tin cube passed US child-resistant certification. It’s the new structure – same as Gen2 version, but there is no hinge and child resistant mechanism tranfers to lid area. Comparing the Gen2 tin, this child resistant tin needs the hard tinplate material on lid to hold rolled inside edge of tin bottom and it consists of the special child-proof tin version – Pushing&Lift that is the first feature on the maket.

The brand can be customized. The classical artwork with attractive printing and high-quality feel of embossing beats the heart of customers. To start your high-end products from a custom tin packaging.

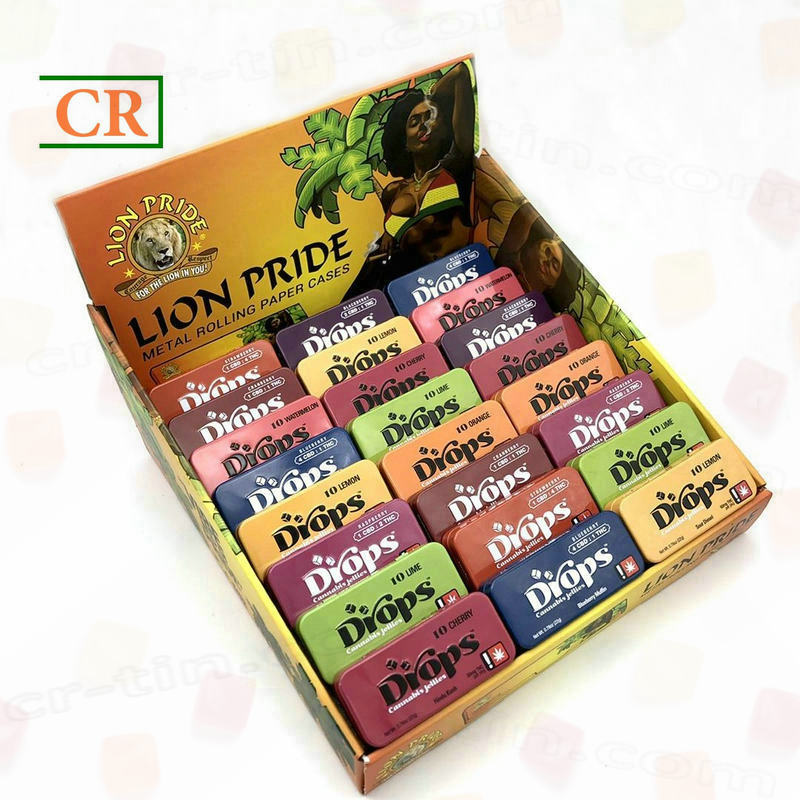

This child resistant tin version is designed for jelleis packaging that belongs to totally new child-proof structure. The inside size 1.16″x1.16″x0.9″ packs 10 mini jellies. Usually, 25pcs tin cube will match a display box as promotional example.

Product detail pictures:

Related Product Guide:

ALS10312 is not child resistant tin box and it’s designed for 6 packs 0.75 or 0.5g CBD pre-rolled joints or smoke herbs packaging. This tin case matches PS insert with outside and inside printing and then add a printing moisture proof butter paper to keep pre-rolls dry and increase the brand impression. For 3 packs pre-rolls, ALR1105613 will be best choice. The structure is the same as ALS10312. The MOQ is 5,000pcs. High Quality for High-End Tin Box - Small Child Resistant Tin Cube – CR , The product will supply to all over the world, such as: Nicaragua, Kenya, Czech, The other option for one gram cartridge is rectangle hinged child resistant tin CRALR1056520. The smooth tin box with flocking foam insert will promote the level of vape cartridge, the hidden child resistant lock increases the appearance, recycling material achieves this luxury packaging, these characters make this hinged child resistant tin box as vape cartridge packaging luxury.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

Products categories

CONTACT US

Please get in touch to order !

-

Whatsapp

-

WeChat

WeChat

-

Ins

Ins

-

Top