Good Quality Child Resistant Tin Box - Small Child Resistant Tin Cube – CR

Good Quality Child Resistant Tin Box - Small Child Resistant Tin Cube – CR Detail:

Description

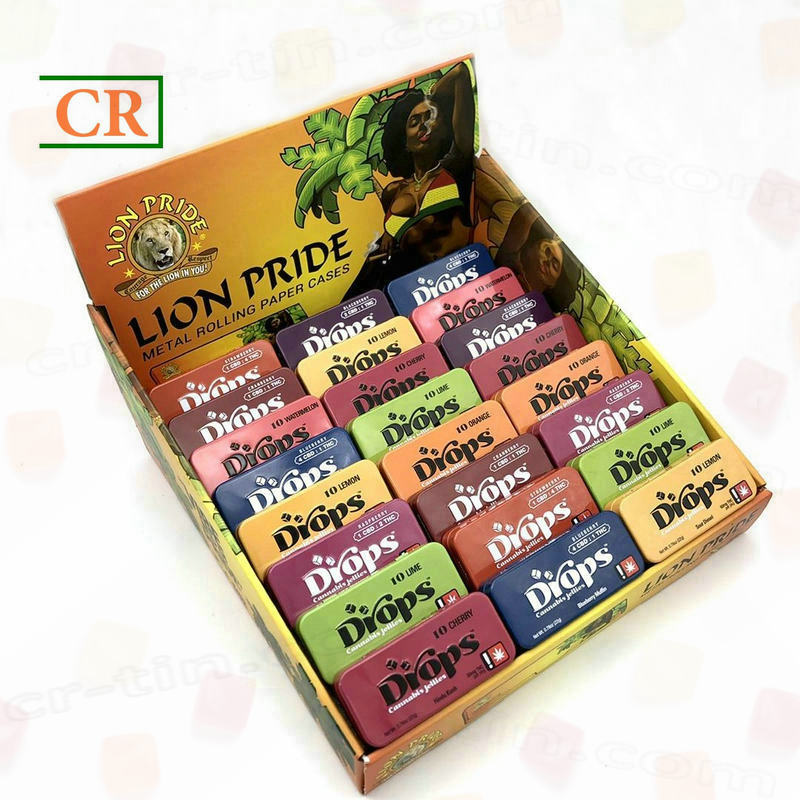

This child resistant version is the same as Gen2 from appearance. It applies special elastic tinplate with complex process for tin body to form this stable child resistant tin cube. There are two slots in lid locks the rolled inside bottom, pushing and lifting lid is the only method to open this tin cube. Designing the child resistant mechanism in lid will ensure no deformation when opening or close this tin cube, three pieces structure ensures this child resistant feature that can be applied all the size, lid-bottom seperating version ensures jellies can be packed directly.

Certified Child Ressitant Version

Custom Printing

Various Usage

This small child resistant tin cube passed US child-resistant certification. It’s the new structure – same as Gen2 version, but there is no hinge and child resistant mechanism tranfers to lid area. Comparing the Gen2 tin, this child resistant tin needs the hard tinplate material on lid to hold rolled inside edge of tin bottom and it consists of the special child-proof tin version – Pushing&Lift that is the first feature on the maket.

The brand can be customized. The classical artwork with attractive printing and high-quality feel of embossing beats the heart of customers. To start your high-end products from a custom tin packaging.

This child resistant tin version is designed for jelleis packaging that belongs to totally new child-proof structure. The inside size 1.16″x1.16″x0.9″ packs 10 mini jellies. Usually, 25pcs tin cube will match a display box as promotional example.

Product detail pictures:

Related Product Guide:

Round child proof tins are the regular CR tin in the market. Most CR mechanisms of round child proof tins belong to Press & Turn with screw. It’s the same as plastic child resistant bottle that belongs to the classical design for pills in many years ago. In order to achieve childproof lock, some companies chose three-lids structure, some companies chose tin with plastic lid or two-lids with accessories. But CR Tin developed a new method to make their round child proof tin to be Lift & Turn. It’s one-piece lid structure that the slot area in the necking of tin body passes through the gap of lid area. This child proof lock could keep the exquisite and smooth appearance with lower cost. Good Quality Child Resistant Tin Box - Small Child Resistant Tin Cube – CR , The product will supply to all over the world, such as: Malta, Canberra, United States, The size of larger Gen1 child resistant tin is 120x60x20mm. Comparing the other child resistant tin box, Gen1’s child resistant lock could match PET window well and no extra accessories for this child resistant tins. The inside space is appropriate to fit one set vape battery pen set. The transparent PET window could display the vape battery pen directly and Gen1’s child resistant lock Press & Lift could be opened without instruction because of the obvious child-resistant lock, the customized PS insert could protect vape pen set well, these characters consist of this attractive vape battery pen set child resistant metal packaging.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Products categories

CONTACT US

Please get in touch to order !

-

Whatsapp

-

WeChat

WeChat

-

Ins

Ins

-

Top